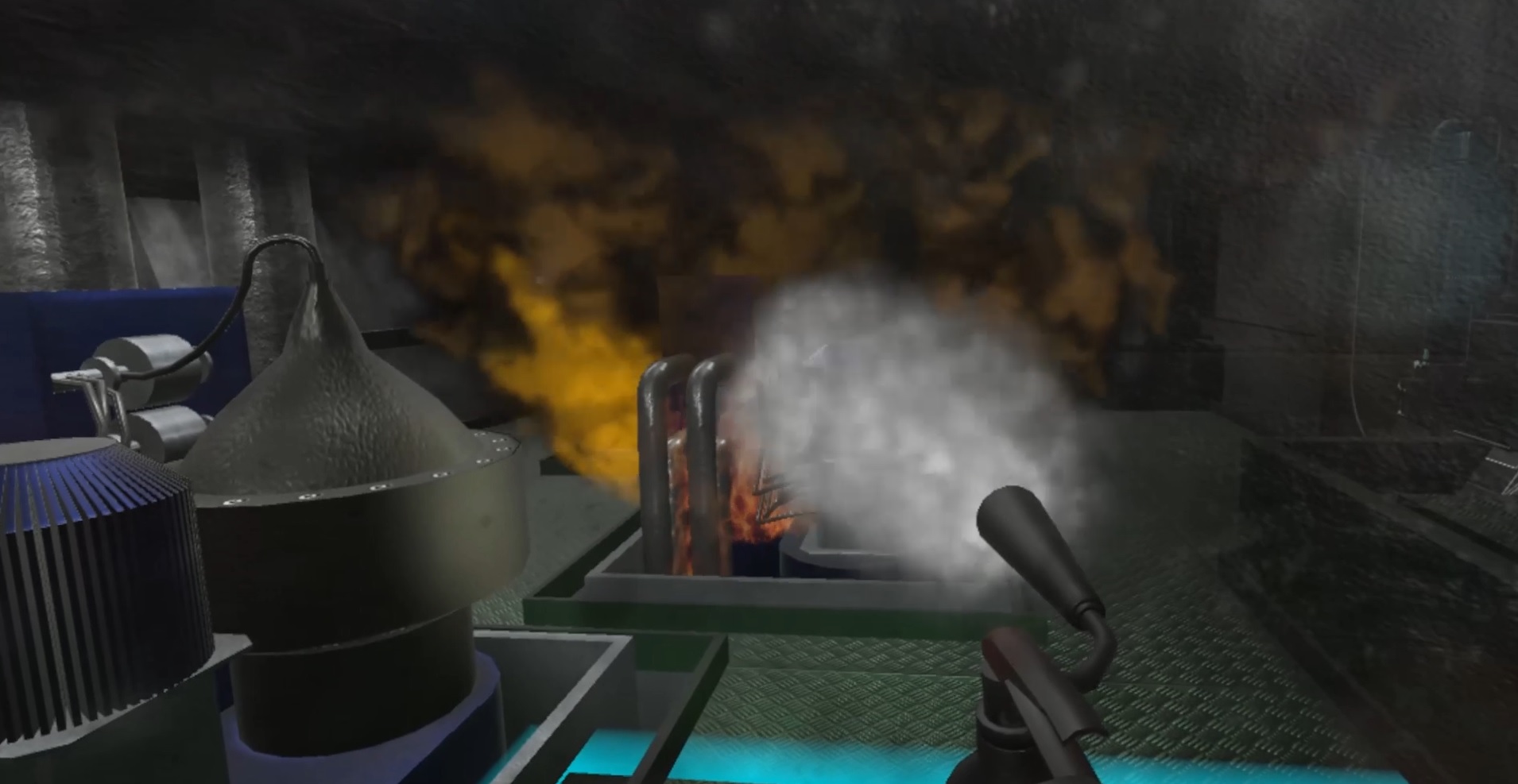

How do you train your work force to operate equipment safely when you run a 24 hour production line and any downtime comes at a cost to the company? Using VR to recreate a virtual factory for UNIPRES, a Tier 1 supplier to Nissan, we have produced a training tool that not only trains staff around specific operational practice, but also reinforcing safe working practices. In this case, the factory runs 24/7 meaning there is very little down time to practice and install best practice, using VR, so instead we have created a lifelike replica of the factory and surrounding environment.

Using the actual real world crane controllers, we have been able to interpret this into the VR world so a user becomes fully immersed in the environment while also being anchored in the real world. This creates a unique training experience that has reduced the cost of training while increasing levels of safety.

VR can also give significant level of productivity improvement by optimising processes such as human assembly line operation. The VR simulations can bring to life the many and varied experiences that can slow or confuse human operators, including line speed, item back-up and the accurate identification and recycling/disposal of faulty product units.

This VR tool was used initially used to demonstrate proof of concept to Unipres, a tier one supplier to Nissan and more, and has since been adopted as part of their overall training procedure.

Unipres are delighted with the new VR training tool and the approach taken by Animmersion and are already planning future developments and enhancements.